Domestic Sewage Treatment Plants

Bio-Pure Sewage Treatment Plant systems consist of 10 models catering from 1-55 persons, meeting the new 2020 regulations

CE Marked & tested to bs en 12566-3

do you need a gravity or pumped domestic sewage treatment plant?

What is the difference between gravity and pumped?

Gravity:

Our Bio-Pure gravity sewage treatment plants use gravity to discharge the processed water into the allocated discharge point. So as long as the discharge point is lower than the outlet you will be fine.

Pumped:

The Bio-Pure pumped sewage treatment plants are for situations when gravity cannot take the discharge water to its discharge point using gravity alone. Our pumped sewage treatment plants can pump the discharge water to locations that are higher than the outlet.

what size domestic sewage treatment plant do i need?

Sizing and Regulations

In order to work out which Domestic Sewage Treatment Plant is suitable for your property, you must abide by the British Water flows and loads guide (4). The table of the loading’s on the guide, set out the suitable sizes of treatment plants for different types of property.

Domestic Dwelling Calculation

A domestic dwelling is fairly straightforward to work out. This is usually the number of bedrooms in the property plus two.

For example, a three-bedroom house becomes five (requiring a Bio-Pure 1 Domestic Sewage Treatment Plant).

Multiple Domestic Dwelling Calculation

However, if the Sewage Treatment Plant is required for more than one property, then two must be added for each dwelling.

For example

a two-bedroom house plus two = four

a three-bedroom house plus two = five,

and a four-bedroom house plus two = six,

Add them all together = fifteen (4+5+6=15). This will require a Bio-Pure 4 Sewage Treatment System.

Non-Residential Property

For a non- residential property, the size of the Bio-Pure required will depend on the purpose of the property. Please contact us and we will be able to work out the correct size Bio-Pure required for your needs.

If you are unsure please contact us and we will be than happy to answer any questions you may have.

Proud members of

Ready to select your Domestic sewage treatment plant?

Bio-Pure Gravity Sewage treatment plant

Please select from the menu below

Bio-Pure Pumped Sewage treatment plant

Please select from the menu below

Want to learn More?

WHAT IS THE BIO-PURE sewage treatment plant AND HOW DOES IT WORK?

The Bio-Pure is a fibreglass conical shaped tank that is used for domestic sewage treatment. The Bio-Pure works on the successful and simple extended aeration method, which means that the solids are treated as well as the liquids. The extended method that we use means that the sewerage is aerated for a minimum of 24 hours. Many other sewage systems only treat the sewage for a few hours. Treating the solids means that the Bio-Pure only needs emptying every 3-5 years typically, making it a simple and easy solution for sewage treatment.

The unit is available in 10 sizes to cater from 1 to 50 persons and can be used for single houses, renovations, barn conversions, small communities, industrial units and camping sites. The Bio-Pure can therefore serve both domestic and commercial properties that have no access to mains drainage. The Bio-Pure is also now available with an integrated pumped outlet.

HOW DOES THE BIO-PURE DOMESTIC SEWAGE TREATMENT PLANT WORK?

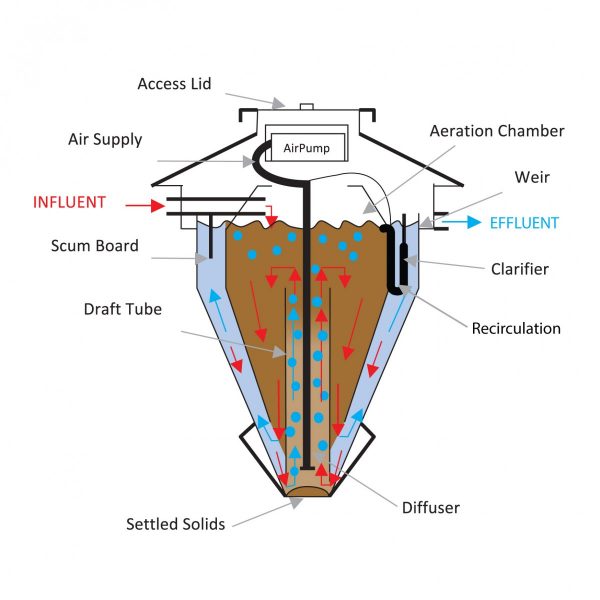

The Bio-Pure is a two chamber unit and consists of a conical tank, with an inner circular aeration chamber inside, which is open at the base.The space between the inner and outer tank is the clarifier chamber.

The draft tube is positioned 100 mm from the base of the clarifier, extends up into the aeration chamber. Air from the compressor housed under the lid is piped to a diffuser in the draft tube.

Raw sewage enters the aeration chamber through the inlet pipe, flowing into the centre of the chamber. Air surging up from the draft tube aerates the sewage, causing an aerobic bacterial colony to establish and digest the organic matter.

As more raw sewage enters the chamber through the inlet pipe, an equal amount of effluent displaces through the open bottom into the clarifier (outer tank).

The quiet conditions in the clarifier allow all the suspended solids to sink to the base of the clarifier and they are drawn back up the draft tube by the upward flow of air for further digestion in the aeration chamber.

The clear effluent rises to the top of the clarifier and passes over a weir into the outlet pipe and is disposed of through a water course or soak away. Further more the Bio-Pure constantly recycles the sewage via gravity and achieves nearly total solids digestion.

Most sewage treatment units consist of three chambers, the first one being a Primary Settlement Tank where the solids form a septic sludge. They require regular emptying by tanker. Because the Bio-Pure digests the solids as well as the organic matter in the liquid, the unit has a much longer emptying interval than any three stage unit. The interval is 3 to 5 years.

The Bio-pure is 96% efficient thus allowing long intervals before de-sludge is required. The waste water is cleaned to a standard of 20 mg/l biological oxygen demand and 30 mg/l suspended solids, meeting the usual discharge level requirement.

The Bio-Pure is fully EN 12566-3 certified

THE PROCESS OF TREATING THE SEWAGE IN 6 SIMPLE STEPS:

- Sewage enters the inner chamber via the inlet pipe

- Air surges up from the draft tube to aerate the solids and liquids for a minimum of 24 hours

- More sewage enters the inner chamber and an equal amount of effluent displaces through and then into the outer chamber (at the bottom of the inner chamber)

- Suspended solids sink to the base of the clarifier and are drawn back up the draft tube for further digestion

- A small quantity of settled effluent from the top of the outer ring clarifying chamber, is drawn back into the centre aeration chamber by a simple airlift system for further digestion.

- Clear effluent rises to the top of the clarifier and passes over the weir into the outlet pipe

WHAT SIZE SEWAGE TREATMENT PLANT DO I NEED?

Sizing and Regulations

In order to work out which Domestic Sewage Treatment Plant is suitable for your property, you must abide by the British Water flows and loads guide (4). The table of the loading’s on the guide, set out the suitable sizes of treatment plants for different types of property.

A domestic dwelling is fairly straightforward to work out. This is usually the number of bedrooms in the property plus two.

For example, a three-bedroom house becomes five (requiring a Bio-Pure 1 Domestic Sewage Treatment Plant).

However, if the Sewage Treatment Plant is required for more than one property, then two must be added for each dwelling.

For example

a two-bedroom house plus two = four

a three-bedroom house plus two = five,

and a four-bedroom house plus two = six,

Add them all together = fifteen (4+5+6=15). This will require a Bio-Pure 4 Sewage Treatment System.

For a non- residential property, the size of the Bio-Pure required will depend on the purpose of the property. Please contact us and we will be able to work out the correct size Bio-Pure required for your needs.

GRADIENTS & INVERTS

What is an Invert Level?

An invert level is the measurement or depth of the drainage pipe from ground level to the base of the pipe as it enters the inlet.

It is important that the sewage enters the tank through the drainage pipe via gravity. A deeper invert may be needed to allow for this.

The invert level is different on every site, and the Bio-Pure can be adapted to meet any individual requirement.

What Is the correct Gradient?

The correct gradient must be established to ensure the sewage is flushed efficiently through the pipe with no build up of solids.

The recommended gradient level is between 1 in 40 (2.5%) and 1 in 110 (0.90%). This means that for every 40 feet horizontally there will be a 1 foot vertical drop (or rise). A gradient of this level will provide sufficient flow velocity.

The gradient level considered ideal is 1 in 80 (1.25%).

Having too steep a gradient will separate the liquids from the solids as the sewage is flowing at a much quicker rate. This will then cause a build up of solids, leading to a blockage within the pipe.However having a gradient that is not steep enough can also cause similar problems.

If you cannot discharge via gravity or if the outlet pipe is above the inlet, then a pumped outlet will be required to pump the effluent over the gradient and into a watercourse or soakaway.

How do you measure a gradient?

The easiest way to measure a gradient is to divide the vertical rise (or drop) by the horizontal distance.

For example, if you have a 2 feet drop or rise on a horizontal distance of 105 feet you divide the 2 together and multiply by 100 to get the percentage gradient of the slope.

2 / 105 = 0.01904761904762 then multiply that by 100 which would give you a 1.9% gradient.

THE COSTS OF RUNNING OUR BIO-PURE SEWAGE TREATMENT PLANTS

De-sludging costs

The Bio-Pure Domestic Sewage Treatment Plant needs to be de-sludged (emptied) on average every 3-5 years. The size and usage can impact on the emptying intervals. Costs on de-sludging can vary.

Electricity

Yes the Bio-Pure system uses electricity to operate 24 hours a day, 365 days a year, you may be interested to know roughly how much the Bio-Pure will cost you to run. Here we can give you a simple formula to work this out.

Watts (of pump) × 24 (hours) × 365 (days) ÷ 1000 × price of kilowatt

For example, if you had a Bio-Pure 1 Domestic Sewage Treatment Plant, you would be using a 44 watt pump, and if your electricity was 14p per kilowatt the total cost would be £53.96

Please note that we can not give you an exact figure as to the cost of running the system, as this will depend on certain factors. You should check the price (per kilowatt) with your own electricity provider, as how much the Bio-Pure sewage treatment system will cost to run will depend on how much you pay for your electricity. This could be more or less than 14p per kilowatt. This depends on location and service provider.

Below is a rough guide on how much each of the 10 Bio-Pure sewage treatment systems will cost to run on the price of 14p per kilowatt.

Bio-Pure E range power consumption

-

Bio-Pure 1 - 27 watts £33.11

-

Bio-Pure 2 - 42 watts £51.50

-

Bio-Pure 3 - 65 watts £79.71

-

Bio-Pure 4 - 84 watts £103.01

-

Bio-Pure 5 - 130 watts £159.43

-

Bio-Pure 6 - 130 watts £159.43

-

Bio-Pure 7 - 210 watts £257.54

-

Bio-Pure 8 - 230 watts £282.07

-

Bio-Pure 9 - 280 watts £343.39

-

Bio-Pure 10 - 280 watts £343.39

*It is important to point out that if you did not need a sewage system because you are connected to mains drainage, you would have the cost of paying for used water and surface water. This is roughly the same cost, if not more, than the cost of the electricity to run the Bio-Pure for a standard domestic dwelling (i.e. a Bio-Pure 1, 2 or 3).

We Build It Ltd are not liable for any differences in costs for running the Bio-Pure. The information provided is intended as a guideline only, and does not include the costs of running the alarm.

THE DO'S & DONT'S FOR THE BIO-PURE SEWAGE TREATMENT PLANTS

We recommend that you follow these do’s and don’t s guidelines to ensure that your Bio-Pure Sewage Treatment plant runs smoothly. Remember that bacteria lives in the Bio-Pure to break sewage down- if you kill off the bacteria the Bio-Pure will not work.

Our personal opinion is not to use bio products. We find them expensive and not particularly effective. You can use normal household products but be careful only to use them in sensible doses.

If you are still unsure or have any questions regarding these guidelines (for looking after the Bio-Pure), please do not hesitate to contact us.

DO

- Try to stick to the same brands of cleaning products Your unit will become quite tolerant to the brands you use

- Use liquids instead of powders e.g. washing and dishwasher Liquids are kinder to the bacteria in the unit

- Spread out your washing through the week Don’t have a ‘washing day’

- Consider washing with ‘Ecoballs’ They work very well and contain no detergent or phosphates, great for your sewage unit (and for allergies). www.ecozone.co.uk

- Service your Bio-Pure once a year It only takes about 1 hour, and will keep your tank functioning properly

- Keep the lid of the Bio-Pure accessible It will be easier for servicing and pumping

- If you experience a problem, call us or a professional Only let experts look after your unit

- Fix leaky faucets This will cause more water to flow into the system

DONT

- Throw any medicines down the sink/loo Antibiotics will kill your unit

- Empty large amounts of detergents and bleach down the sink/loo Pour the buckets down your outside drains, as these are not connected to the unit

- Allow anti-bacterial substances, (hand wash, dettox, etc) to enter the unit These will KILL the unit. Apply the products with kitchen towels and throw them in a bin

- Pour sterilizing fluids (Milton, etc.) down the sink These will KILL the unit

- Pour milk down the sink The BOD of milk is too high and the bacteria will suffer

- Put sanitary items, nappy liners, baby wipes, cotton wool, etc. down the toilet Cotton wool ‘shreds’ when wet, is very slow to degrade and blocks everything

- Empty cooking oil down the sink The oil will coat and smother the friendly bacteria in your unit

- Allow a ‘hot tub’ or ‘spa’ to discharge into this unit The volumes are too great and will flush untreated sewage through your unit. If chlorination is used, this will also KILL the bacteria in the unit

- Empty home-brew residues down the sink Yeasts will take over your unit!

- Install a waste disposal unit The unit would need to be three times the size to digest the additional organic waste produced

COMPARE OUR SEWAGE TREATMENT PLANTS & SEPTIC TANKS

Below you will see a table showing how the Bio-Pure Sewage Treatment Systems and its extended aeration method of treating sewage fairs against a three stage unit and a traditional septic tank.

The Bio-Pure range have been specifically designed to overcome many of the associated problems with a three stage unit and a septic tank. The Bio-Pure systems are an affordable, high quality sewage treatment plant, with a long term guarantee making it the most practical purchase.

BIO-PURE

Easy Installation = Yes

Concrete Required = No

Suitable for a high water table = Yes

Visually unobtrusive = Yes

Internal Moving Parts = No

Where can I discharge to? = Watercourse, soakaway, ditch

Clean effluent = Yes, very

Electricity required = Yes

Smelly primary settlement chamber = No

Emptying interval = 3-5 years

Rough electrical cost per annum = £48

THREE STAGE UNIT

Easy Installation = Sometimes

Concrete Required = Mostly

Suitable for a high water table = Yes

Visually unobtrusive = Sometimes

Internal Moving Parts = Mostly

Where can I discharge to? = Watercourse, ditch etc

Clean effluent = Yes

Electricity required = Yes

Smelly primary settlement chamber = Yes

Emptying interval = Annually

Rough electrical cost per annum = £80

SEPTIC TANK

Easy Installation = Sometimes

Concrete Required = Yes

Suitable for a high water table = No

Visually unobtrusive = Sometimes

Internal Moving Parts = No

Where can I discharge to? = Soakaway or reed bed

Clean effluent = No

Electricity required= No

Smelly primary settlement chamber = Yes

Emptying interval = Annually

Rough electrical cost per annum = N/A

Please note, the information provided is intended as a guideline as all septic tanks and three stage units are different. Pricing is provided as a rough estimate as this will depend upon individual cirmcumstances. The electrical cost provided for the Bio-Pure is based on a Bio-Pure 2 from our E Range (based on 11p per kilowatt).

Sewage Treatment Plants vs Septic Tank

The Bio-Pure sewage treatment systems can be discharged directly to a watercourse or groundwater. When you consider whole life costs they are lower priced, smaller and cheaper to install with less pollution.

Your local authority and/or the Environment Agency can refuse septic tanks and may specify a package treatment plant in many areas of the UK, it is essential to check what is acceptable, We Build It Ltd can advise you every step of the way.

The traditional septic tank may seem very cheap initially, however you will require a soakaway to discharge because the final effluent is not clean enough to discharge into a watercourse or ditch etc. A soakaway for a septic tank can be problematic because a sufficiently large area of land is required, and not all areas are suitable for a soakaway.

The life expectancy of a soakaway from a septic tank is roughly 10 years compared to 25 years from a packaged sewage treatment plant. Soakaways are prone to blocking from a septic tank due to unclean effluent.

The Bio-Pure may therefore be a better solution for your wastewater treatment and possibly cheaper than installing a septic tank.

Discharges from septic tanks to a watercourse are not allowed under the general binding rule. If you have a septic tank that discharges directly into a watercourse you will need to replace or upgrade this by 1st January 2020 or when you sell your property if before this date. If the Environment agency find evidence that the watercourse is being polluted, you will need to replace the tank earlier than January 2020. Typically you will be given a year to sort however this is agreed upon on a case by case basis.

Septic tank Conversion

If you have an existing septic tank We Build It can supply you with a Septic Tank Conversion Unit which can be put in line with the septic tank to further treat the sewage before discharging into a water course, ditch or soakaway. We would only recommend this where it is uneconomical or difficult to remove the existing septic tank, this process would still give results better than the normal discharge consent levels. The unit offers a discreet solution to on-site secondary treatment from a septic tank or underperforming treatment plant, by using extended aeration and plastic media technology.

Questions to ask Sewage Treatment Plant Suppliers

Before You Spend Your Money Consider these Questions to ask:

- Where is it manufactured?

- Who Tested It?

- When Was It Tested?

- Can I Have a Copy Of The Report?

- If Not Why Not?

- The True Power Consumption?

- How Often Does It Need De-Sludging?

- Do You Have References Off Customers?

Once you obtain this Information now Check:

- The Test Facility Used

- Was It Done During The Warmer Months? This Enhances The Test Results

- How Often Was It De-Sludged During The Test

- How Many kWh/d did it use?? Check Out The Suppliers Claims

Ready to invest in your new domestic sewage treatment plant?

Get in touch today for free, friendly and impartial advice from one of our team or fill out the form below and we will contact you at a time that is convenient to you.

Our mission is to delight our clients With Outstanding service

We are just a click or call away to serve you

Our staff are trained to give you straight forward and easy to follow advice for all of your Sewage Treatment Plant needs.

All of our sewage treatment plants come with easy to follow installation and service manuals, as well as free telephone assistance by specialist installers.

We can also offer full or assisted installations at very competitive rates. We pride ourselves on offering the best GRP products on the market backed up by proper old-fashioned customer service – (dial straight through and speak to our specialists, no automated service or queuing system).

We Build It Ltd is a member of British Water and we ensure that our Sewage Treatment Plants exceed all industry standards.

We Build It Ltd

Kingsnordley Farm

Kingsnordley

Bridgnorth

Shropshire

WV15 6EU

Phone: 01746 781782

Freephone: 0800 731 9421

Email: sales@webuildit-ltd.co.uk